How Biomass Quality Impacts Final Yield in Cannabis Cultivation and Processing

In the ever-evolving world of cannabis cultivation and processing technology, one critical but sometimes overlooked factor stands tall in determining the success of any cannabis operation: biomass quality.Whether you are a cultivator, extractor, or processor, understanding how the quality of cannabis biomass influences the final yield and product quality is essential. This article dives deep into the nuances of biomass quality and elucidates it’s direct connection to the final yield, impacting everything from cannabinoid potency to processing efficiency.

Understanding Cannabis Biomass and Why Its Quality Matters

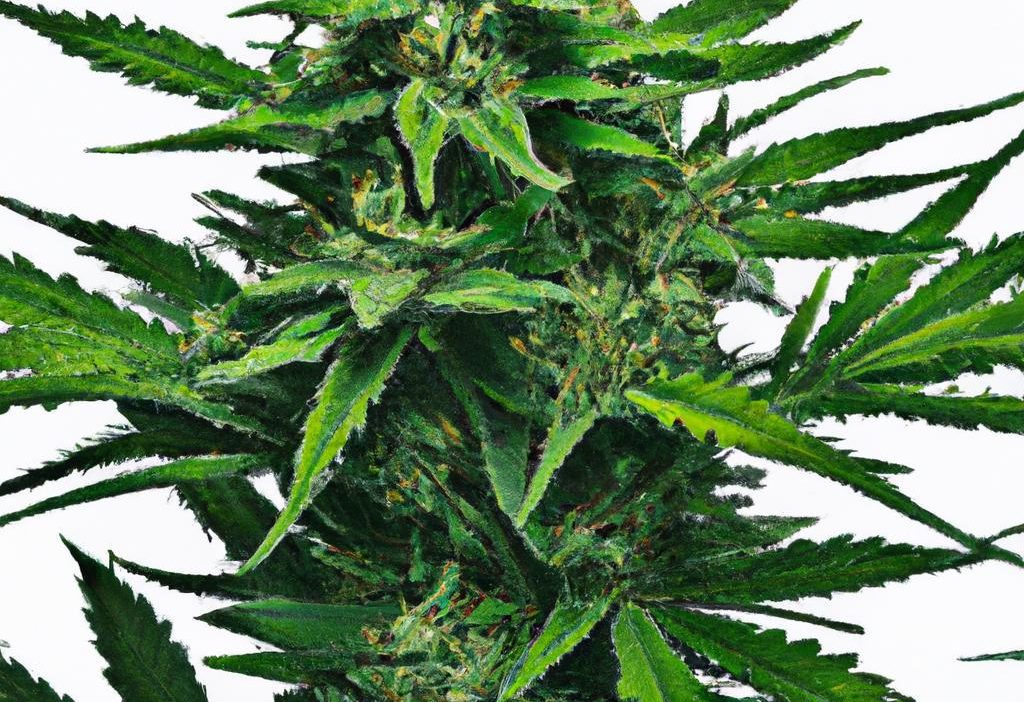

Biomass in the cannabis industry refers to the harvested plant material that is afterward processed to extract cannabinoids, terpenes, and other valuable compounds. Biomass includes flowers (buds), trim (leaves and small stems), and sometimes whole plant matter depending on the processing method. The quality of this biomass is central to maximizing final yield, which generally means higher cannabinoid concentration, better terpene profiles, and overall more potent and marketable cannabis products.

Key Factors Influencing Cannabis Biomass Quality

- Genetics: Starting with superior cannabis strains ensures higher cannabinoid and terpene content, thus better biomass quality.

- Growing Conditions: Optimal lighting, temperature, humidity, and nutrient management impact biomass density and chemical composition.

- Harvest Timing: Harvesting at peak trichome maturity enhances cannabinoid concentration and terpene richness.

- Post-Harvest Handling: Proper drying and curing prevent mold, degradation, and loss of potency.

- Trim quality: Quality trimming influences purity of biomass,removing excess leaves that can reduce extraction efficiency.

The Direct Relationship Between Biomass Quality and Final Yield

Measuring final yield in cannabis is not just about weight-it also hinges on the potency and purity of the extractable compounds in the biomass. here’s how biomass quality affects yield:

1. Cannabinoid and terpene Content

High-quality biomass has elevated levels of cannabinoids like THC and CBD, as well as aromatic and therapeutic terpenes. This translates into a higher percentage of active compounds during extraction.

2. Moisture Content

Biomass with ideal moisture content (typically around 10-12%) ensures optimal extraction efficiency.Too wet, and the material will degrade or clog processing equipment; too dry, and volatile compounds may evaporate, decreasing yield.

3. Purity and Contamination

Contaminants such as stems, seeds, or foreign plant matter reduce the overall cannabinoid yield. High-purity biomass improves extraction clarity and efficiency.

How Biomass Quality Affects Processing Equipment & Techniques

Biomass quality plays a crucial role in how well cannabis processing equipment functions,including extraction machines,grinders,and presses. Poor-quality biomass can clog, wear down, or lower the efficiency of this expensive equipment. Here’s a rapid overview:

| Processing Step | Impact of Poor Biomass quality | Benefit of High-Quality Biomass |

|---|---|---|

| grinding/Shredding | Clogs machinery; inconsistent particle size | Uniform particle size; smooth operation |

| Extraction (e.g., CO2, ethanol) | Lower cannabinoid recovery; solvent contamination | Higher extraction efficiency; pure and potent extracts |

| drying and Curing | Increased risk of mold and loss of terpenes | Preserves quality; enhances flavor and potency |

Practical Tips to Optimize Cannabis biomass Quality

Enhancing biomass quality should be your goal if you want to maximize your cannabis final yield and product quality. here are some actionable tips:

- Monitor and control your cultivation environment closely to reduce plant stress and disease risk.

- Harvest at the right time-use magnification tools to judge trichome maturity for peak potency.

- Implement gentle handling post-harvest to avoid bruising and degradation of delicate cannabinoids.

- Invest in precision trimming machines or skilled manual trimmers to enhance purity of biomass feedstock.

- Regularly calibrate and maintain processing equipment to handle biomass efficiently and reduce downtime.

- Test biomass for moisture and cannabinoid profiles frequently to adjust curing and processing parameters accordingly.

Case Study: Biomass Quality Impact on Extraction Yield

A cannabis extraction facility in California implemented stricter biomass quality controls including standardized drying protocols and genetic selection for cannabinoid-rich strains. After six months:

- Extraction efficiency increased by 15% due to higher cannabinoid concentration in biomass.

- Operational downtime reduced by 20% thanks to better-prepared plant material causing fewer clogs.

- Final product potency rose by an average of 8% leading to stronger market demand and higher sales.

This demonstrates a clear link between biomass quality and measurable improvements in final yield and operational effectiveness.

Conclusion: Prioritize Biomass quality for Maximum cannabis Yield and Profitability

In the complex and competitive realm of cannabis production, paying close attention to the quality of your biomass can be the difference between marginal and spectacular final yields. From cultivation through harvesting and post-processing, every step impacts the chemical richness and physical purity of the biomass.Investing in superior genetics, optimal growing conditions, and meticulous post-harvest care will yield clean, potent material that maximizes extraction efficiency and product quality.

Better biomass quality means more potent cannabis extracts, smoother processing, and ultimately, higher market value products. Whether you are a grower, processor, or extractor, focus on enhancing biomass quality to unlock the full potential of your cannabis operation.