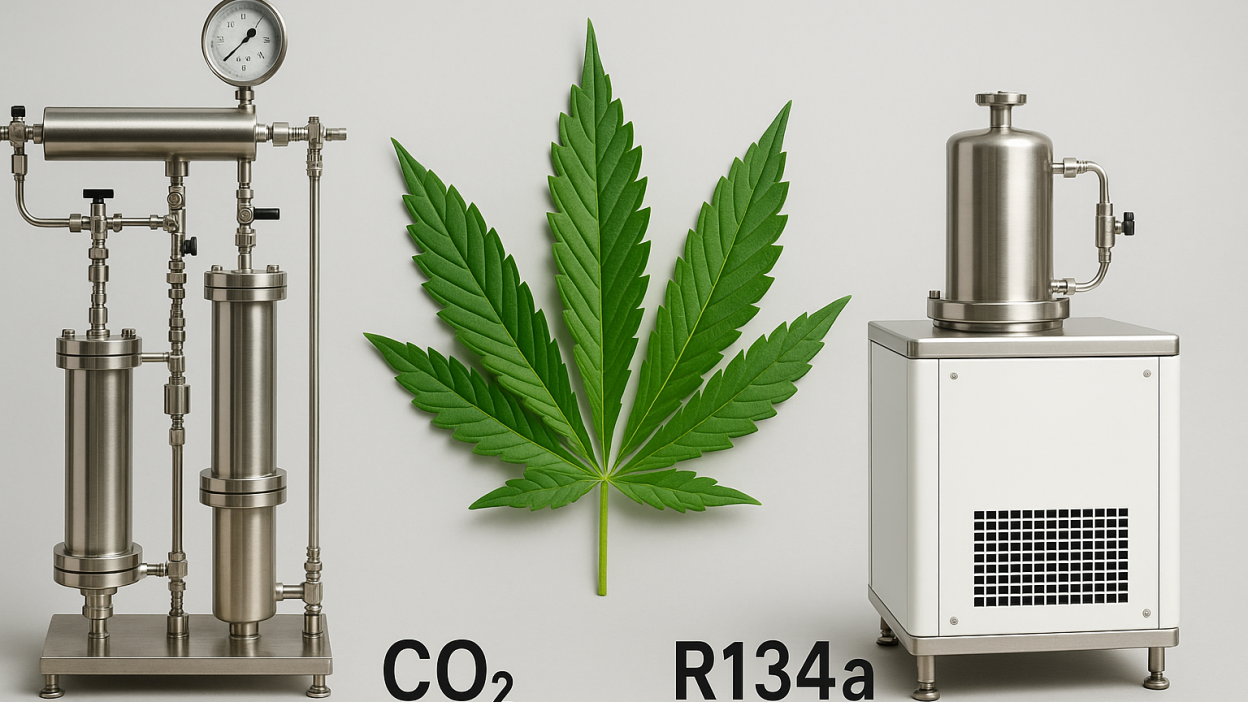

Cannabis extraction technology has evolved dramatically over the past decade, with processors constantly seeking methods that deliver superior quality while maintaining operational safety and economic viability. Two extraction methods have emerged as leaders in the clean extraction space: supercritical CO₂ and R134a extraction through systems like PURE5™. Understanding the fundamental differences between these technologies is crucial for processors making equipment investments that will define their operations for years to come.

The Science Behind Each Method

CO₂ Extraction Technology

Supercritical CO₂ extraction operates by pressurizing carbon dioxide beyond its critical point (1,071 PSI and 88°F), creating a state where CO₂ exhibits properties of both liquid and gas. In this supercritical state, CO₂ becomes an effective solvent for cannabinoids and terpenes while remaining non-toxic and leaving no residual solvents in the final product.

R134a Extraction Technology

R134a (1,1,1,2-Tetrafluoroethane) extraction utilizes a refrigerant-grade solvent that operates at significantly lower pressures and temperatures than CO₂ systems. The PURE5™ methodology leverages R134a’s unique molecular properties to selectively extract desired compounds while naturally excluding unwanted materials like chlorophyll, waxes, and water-soluble impurities.

Operational Pressure and Temperature Comparison

The operational parameters represent one of the most significant differences between these extraction methods. CO₂ systems typically operate at pressures ranging from 1,500 to 5,000 PSI, with temperatures between 70-100°F for supercritical extraction. These high pressures require robust, expensive equipment and present inherent safety considerations related to pressure vessel management.

R134a extraction systems operate at dramatically lower pressures, typically under 300 PSI, with processing temperatures often below ambient conditions. This low-pressure operation reduces equipment costs, simplifies safety protocols, and minimizes the risk of catastrophic pressure-related failures that can occur with high-pressure CO₂ systems.

Equipment Costs and Infrastructure Requirements

Initial Investment Comparison

CO₂ extraction equipment represents a significant capital investment, with commercial systems ranging from $200,000 to over $1 million depending on throughput capacity. The high-pressure nature of CO₂ systems requires precision-engineered components, specialized pumps, and robust pressure vessels that drive up manufacturing costs.

R134a extraction systems like PURE5™ require substantially lower initial investments due to their low-pressure operation. The reduced complexity of components and lower engineering tolerances make these systems more accessible to smaller processors and those entering the extraction market.

Facility Infrastructure

CO₂ extraction facilities must accommodate heavy equipment, specialized electrical requirements, and comprehensive safety systems. The weight and footprint of CO₂ systems often require reinforced flooring and dedicated utility connections, adding to total project costs.

R134a systems offer greater installation flexibility with lighter equipment weights and standard electrical requirements. This flexibility allows processors to establish operations in a wider variety of facilities without extensive modifications.

Safety Profile Analysis

Both extraction methods offer significant safety advantages over hydrocarbon-based systems, but they differ in their specific risk profiles and operational requirements.

CO₂ Safety Considerations

While CO₂ is non-flammable and generally recognized as safe, it presents unique challenges. CO₂ displacement can create oxygen-deficient environments, requiring comprehensive ventilation systems and gas monitoring. The high pressures involved in supercritical extraction demand rigorous pressure vessel inspection protocols and specialized training for operators.

R134a Safety Advantages

R134a extraction eliminates both flammability and high-pressure risks. As a refrigerant with decades of safe use in various industries, R134a has a proven safety record. The low-pressure operation minimizes equipment-related hazards, and the non-toxic nature of R134a reduces health risks for operators.

Product Quality and Extraction Efficiency

CO₂ Extraction Results

CO₂ extraction produces clean, solvent-free concentrates with good cannabinoid recovery rates. However, the process can be harsh on delicate terpenes, particularly at higher pressures and temperatures. Multiple extraction passes are often required to achieve complete cannabinoid recovery, extending processing times and increasing operational costs.

R134a Extraction Quality

R134a extraction excels in terpene preservation due to its low-temperature operation. The selective nature of R134a naturally excludes many unwanted compounds, resulting in cleaner extracts with minimal post-processing requirements. Single-pass extraction efficiency often exceeds that of CO₂ systems, improving throughput and reducing processing costs.

Processing Speed and Throughput

CO₂ extraction typically requires longer cycle times due to the multiple extraction phases needed for complete compound recovery. The warming and cooling cycles, combined with depressurization requirements, can extend processing times significantly.

R134a systems demonstrate superior processing speed with faster cycle times and higher throughput capabilities. The efficient single-pass extraction reduces the total time from plant material to finished concentrate, improving operational efficiency and reducing labor costs.

Environmental Impact and Sustainability

CO₂ Environmental Profile

CO₂ extraction utilizes a naturally occurring compound with no ozone depletion potential. However, CO₂ systems consume significant energy for compression and temperature control, contributing to larger carbon footprints during operation.

R134a Sustainability

R134a has zero ozone depletion potential and operates in closed-loop systems that minimize environmental release. The lower energy requirements of R134a extraction contribute to reduced operational carbon footprints, particularly when considering the elimination of energy-intensive post-processing steps.

Post-Processing Requirements

CO₂ extracts often require extensive post-processing including winterization, filtration, and distillation to achieve desired purity and consistency. These additional steps increase processing time, equipment requirements, and operational costs while potentially degrading product quality.

R134a extraction produces cleaner initial extracts that require minimal post-processing. The selective extraction characteristics mean fewer impurities to remove, reducing the need for winterization and extensive filtration while preserving product integrity.

Economic Analysis and ROI

When evaluating total cost of ownership, R134a extraction systems often demonstrate superior return on investment due to lower initial costs, reduced operational expenses, and higher processing efficiency. The combination of faster processing, minimal post-processing requirements, and lower facility costs contributes to improved profitability.

CO₂ systems may offer advantages for very large-scale operations where the higher initial investment can be amortized across significant production volumes, but for most commercial processors, the economic advantages favor R134a extraction.

Making the Right Choice for Your Operation

The choice between R134a and CO₂ extraction depends on specific operational priorities, production volumes, and market requirements. For processors prioritizing safety, product quality, processing efficiency, and economic performance, R134a extraction through systems like PURE5™ offers compelling advantages.

As the cannabis industry continues to mature and competition intensifies, the operational efficiencies and economic advantages of R134a extraction position it as the preferred choice for forward-thinking processors seeking to build sustainable, profitable extraction operations.