Why Your Extract Smells Burnt: Extraction Gone Wrong | Cannabis Science & Processing

Cannabis extraction is an art and a science fused together, aiming to capture the purest flavors, cannabinoids, and terpenes that the plant has to offer.Though, sometimes, extracts develop a burnt smell-an unpleasant scent that signals a problem during the extraction or post-processing stages. Understanding why your cannabis extract smells burnt is crucial for both commercial producers and home extractors to optimize quality and preserve the true essence of cannabis. In this article, we’ll explore the common causes behind burnt smell in extracts, how it fits into the broader cannabis extraction process, and practical tips for avoiding these pitfalls.

The Science Behind Cannabis Extraction and Why Smell Matters

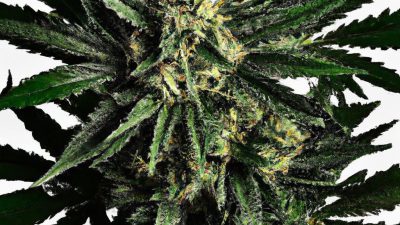

Cannabis extraction involves isolating cannabinoids like THC, CBD, terpenes, and other beneficial compounds from plant material, usually thru solvent-based or solventless methods. Popular techniques include CO2 extraction, butane hash oil (BHO) extraction, ethanol extraction, and rosin pressing.

One of the best indicators of the quality of an extract is its aroma and flavor profile. A burnt or charred smell typically signals thermal degradation of cannabinoids and terpenes-compounds sensitive to heat-which detracts from both potency and sensory experience.

Key Terms to Know:

- Terpenes: aromatic oils responsible for cannabis flavors and scents.

- Cannabinoids: Chemical compounds in cannabis affecting effects, like THC and CBD.

- thermal Degradation: Breakdown of compounds caused by excessive heat.

Why Does Your Cannabis Extract Smell Burnt? Common Extraction Mistakes

An extract smelling burnt isn’t caused by a single issue but frequently enough results from multiple errors during harvesting, extraction, or post-processing.

1. Excessive Heat During Extraction

One of the most common reasons for burnt aromas is overheating during the extraction phase.Heat-sensitive terpenes begin to degrade at temperatures as low as 130°F (54°C), while cannabinoids start decarboxylating at higher temperatures.

- What happens: Too high temperatures cause terpene evaporation or breakdown, resulting in burnt, acrid odors.

- How to avoid: Use precise temperature controls, monitor extraction carefully, and prefer gentle methods like cold ethanol extraction or optimized CO2 setups.

2. Improper Vacuum Purging or Residual solvents

Post-extraction purging is critical to remove leftover solvents. Insufficient vacuum purge or overheating in this step can cause burning smells.

- What happens: Overheating vacuum ovens to speed purging degrades the extract’s aroma compounds.

- How to avoid: Maintain controlled vacuum temperatures (usually below 110°F or 43°C) and ensure adequate purge time.

3.Contamination From Burnt Plant Material

Sometimes, poor-quality starting material that has been cured or stored improperly can already emit burnt or harsh aromas. Additionally,burning plant matter when preparing the biomass will introduce burnt odors into the final product.

- Tip: Use fresh, high-grade cannabis flower or trim, and avoid any open flame or scorched residue in your prep area.

Additional Factors affecting Extract Aroma

Oxidation & Storage Conditions

Exposure to oxygen can cause terpene oxidation, producing off-smells akin to burnt or stale extracts.

- Store extracts in airtight,dark containers to preserve freshness.

- Keep at optimal temperatures (below room temp) to slow degradation.

Extraction Equipment Maintenance

Dirty or burnt extraction chambers, damaged heating elements, or worn gaskets can contaminate your extract with burnt aromas.

- Regular equipment cleaning ensures no carbon buildup introduces unwanted flavors.

Table: Common Causes of Burnt Smell in Cannabis Extracts & Solutions

| Cause | Effect on Extract Aroma | Practical Solution |

|---|---|---|

| Excessive extraction heat | Terpene loss, burnt smell | Use temperature controls; extract under 130°F |

| Overheating during vacuum purge | Thermal degradation, off-odor | Maintain vacuum below 110°F; purge longer |

| Poor starting material quality | Burnt or stale flavors | Use fresh, well-cured cannabis |

| Contamination from dirty equipment | unpleasant burnt aroma | Clean equipment regularly |

Practical tips to Avoid Burnt Smells in Cannabis Extraction

- Monitor Extraction Temperatures: Use digital thermometers and automated controls to maintain safe thermal thresholds.

- Invest in Quality Equipment: Modern extraction systems have built-in safeguards against overheating.

- Vacuum Purge with Care: Avoid rushing purging; use gentle heat and verify complete solvent removal with proper lab tests.

- Store Properly: Keep extracts in amber glass jars in cool, dry environments to avoid oxidation.

- Maintain Equipment Hygiene: Routine cleaning prevents buildup of carbon residue and flavor contamination.

Case Study: Avoiding Burnt Smell in Butane Hash Oil (BHO) Extraction

A professional cannabis processor experienced consistent burnt smell in their BHO extracts. After thorough review, they identified the vacuum purge temperature was set to 140°F, too high for preserving terpenes. Implementing a new protocol lowering purge temps to 90-100°F extended purge duration and utilized vacuum pumps with higher capacity. The resulting extracts had vibrant aroma profiles with zero burnt smell, significantly improving customer satisfaction.

conclusion

Recognizing why your cannabis extract smells burnt is key to mastering cannabis extraction science and delivering premium-quality products. burnt smells undermine the potency, flavor, and overall consumer experience. By carefully managing extraction temperatures, proper vacuum purging, starting with quality biomass, and maintaining equipment, you can avoid the dreaded burnt aroma. As cannabis technology and post-processing techniques continue to evolve, staying educated and mindful about each step will help you produce extracts that truly showcase the plant’s natural excellence.

Master the art and science of clean cannabis extraction, and your extracts will never smell burnt again!