issues“>

issues“>

Troubleshooting Smell, Color, and Clarity Issues: A Comprehensive Guide

Whether you are dealing with water, beverages, industrial products, or household items, issues related to smell, color, and clarity can be frustrating and sometimes alarming. Understanding the underlying causes and learning how to troubleshoot these problems can save time, money, and improve product quality or safety. In this comprehensive guide, we explore common causes, swift fixes, and preventive measures to help you effectively manage these sensory quality concerns.

Understanding Smell, Color, and Clarity Issues

Smell, color, and clarity are critical sensory indicators often used to assess the quality and safety of various substances-from drinking water to pharmaceuticals. Changes in these properties can indicate contamination,chemical reactions,or process failures. Identifying these problems early can help you address root causes before they escalate.

Why These factors Matter

- Smell: A sudden or unusual odor may suggest bacterial growth, chemical contamination, or spoilage.

- Color: Changes in color can indicate oxidation, impurities, or the presence of foreign materials.

- Clarity: Reduced clarity, cloudiness, or particulate matter often signals suspended solids, microbial contamination, or improper filtration.

Common Causes of Smell, Color, and Clarity Problems

| Issue | Typical causes | Examples |

|---|---|---|

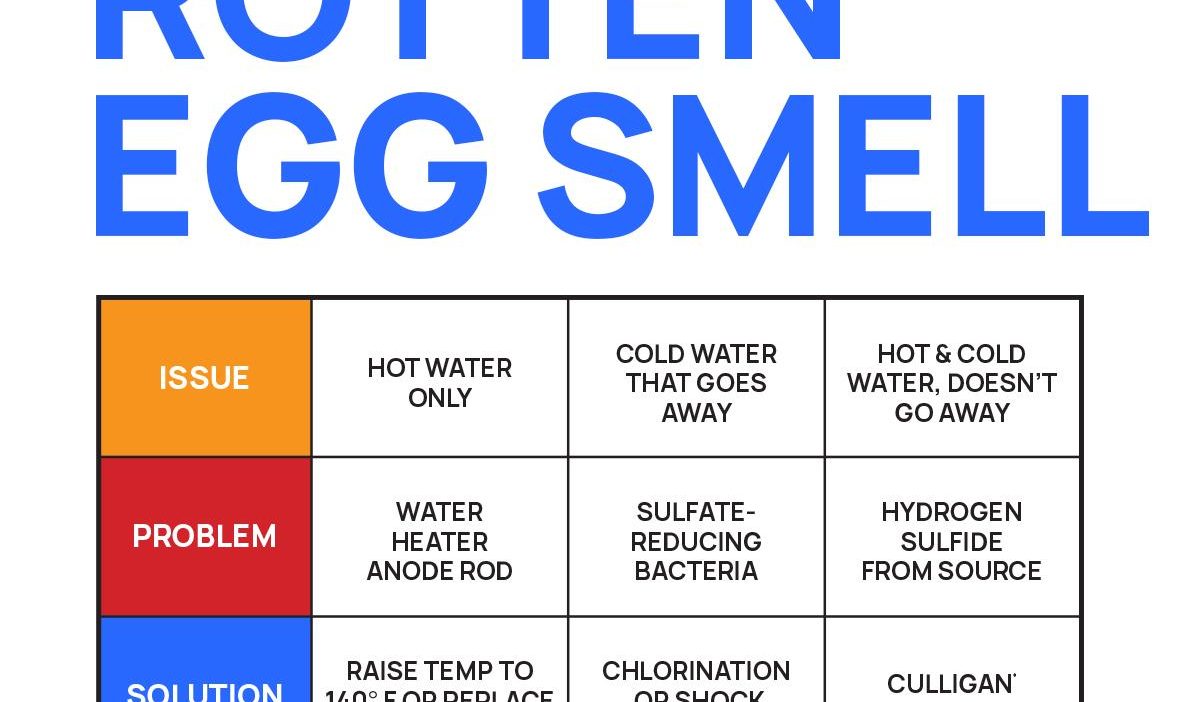

| unpleasant Smell | Bacterial contamination, chemical reactions, organic material decomposition | Rotten egg smell in water, musty odor in paint |

| Discoloration | Rust, contamination, oxidation, dye bleeding | Yellowish water, brown patches on fabrics |

| Cloudiness or Lack of Clarity | Suspended solids, microbial growth, emulsions, incomplete filtration | Milky appearance in beverages, hazy liquids, sediment in water |

Step-by-Step Troubleshooting Guide

1. Identify the Source

Start by determining whether the issue originates from raw materials, processing equipment, storage conditions, or the surroundings.

2. Conduct Sensory and Basic Tests

- Smell test: Compare affected and unaffected products.

- Visual inspection: Check for discoloration or visible particulates.

- Clarity test: Use a light source to assess clarity or turbidity.

3. Perform Chemical and Microbiological Analyses

If sensory inspection points to contamination, lab testing helps identify:

- Bacterial or fungal growth

- Chemical contaminants or pH imbalances

- Presence of heavy metals or other pollutants

4. Evaluate Equipment and Procedures

inspect filters, pipes, tanks, and processing machinery for cleanliness, wear, or rust. Verify if procedures follow safety and industry standards.

Practical Tips for Preventing and Fixing Smell, Color, and Clarity Issues

- maintain hygiene: Regularly clean and sanitize storage and processing equipment.

- Control storage conditions: keep items in cool,dry environments to reduce microbial growth.

- Use proper filtration: Ensure filters are suited to the product type and replaced regularly.

- Monitor raw materials: Source from trustworthy suppliers and test materials before use.

- Apply antioxidants or stabilizers: For products sensitive to oxidation, use additives to prevent discoloration.

- Track shelf life rigorously: Use FIFO (First In, First Out) stock rotation to avoid spoilage.

Case Study: Resolving Water Cloudiness in a Small Beverage Manufacturing Plant

A small beverage manufacturer noticed persistent cloudiness and unusual odor in their bottled water line. Initial inspections suggested possible microbial contamination. After detailed testing, they traced the problem to biofilm buildup inside filtration pipes.

Implementing a thorough cleaning and disinfection regime, upgrading filter quality, and training staff on hygiene protocols eliminated the cloudiness and odor issues.Regular monitoring was established to ensure ongoing product clarity and freshness.

Firsthand experiance: How Regular Maintenance Prevented Product Quality Decline

“In my five years working in a cosmetic production facility,we faced challenges with discoloration and smell changes during warmer months. Instituting a weekly deep cleaning of tanks and switching to stainless steel piping helped considerably reduce these issues. Now our customers consistently praise the clarity and fragrance of our products.” – quality Manager, Cosmetics Industry

benefits of Proper Troubleshooting and Maintenance

- Enhances product safety and consumer trust

- Reduces waste and production downtime

- Improves compliance with regulatory standards

- prolongs equipment life and lowers operational costs

Summary Table: Troubleshooting Checklist

| Step | Action | Expected Outcome |

|---|---|---|

| 1 | Visual & smell inspection | Identify obvious issues |

| 2 | Lab testing (chemical, microbial) | Pinpoint contamination or chemical causes |

| 3 | Equipment and process audit | Locate maintenance or procedural gaps |

| 4 | Implement corrective actions | Resolve quality issues |

| 5 | Ongoing monitoring | maintain consistent product quality |

Conclusion

Smell, color, and clarity issues can occur in a wide range of products and materials, often indicating underlying quality problems. By understanding the common causes and adopting a systematic troubleshooting approach, you can quickly identify and fix these sensory quality challenges. Coupled with regular maintenance, hygiene, and monitoring, these practices ensure your products remain safe, appealing, and compliant with industry standards.

Stay proactive with quality control, and your customers will notice the difference in every clear, fresh-smelling, and perfectly colored product you offer.