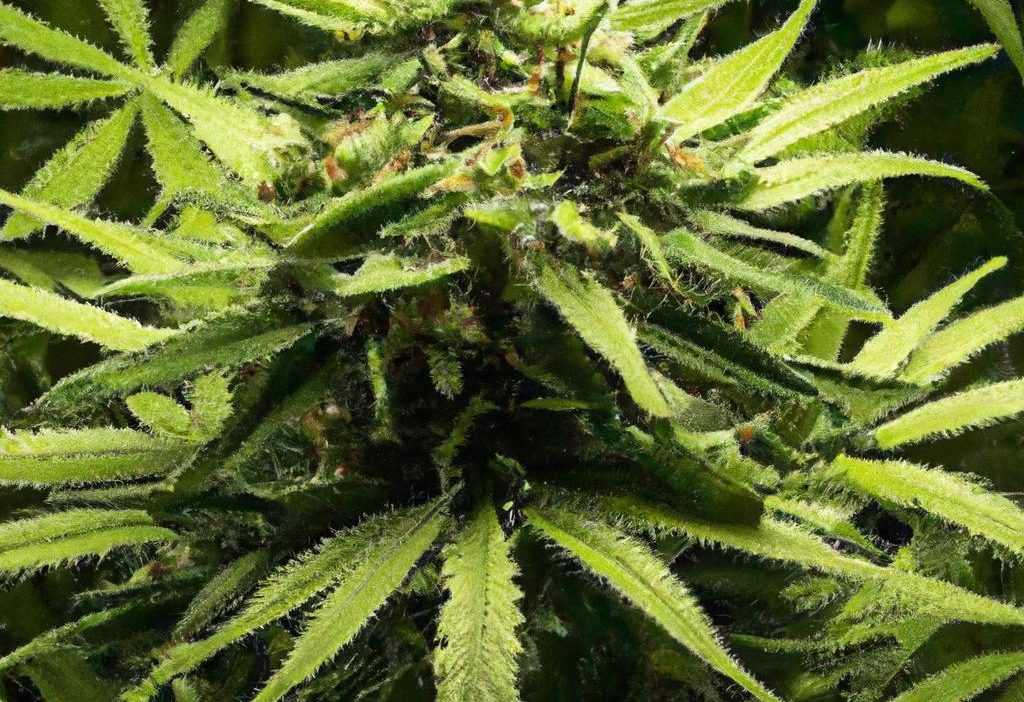

Scaling R134a Extraction from Craft to Commercial Volumes in Cannabis Processing

The cannabis industry is evolving rapidly, with innovations in cannabis extraction technologies driving quality and efficiency. Among various extraction methods, R134a extraction stands out as a unique and environmentally friendly technique for isolating cannabinoids and terpenes. As demand skyrockets, scaling R134a extraction from craft batches to commercial volumes poses specific challenges and opportunities.

understanding R134a extraction in Cannabis Science

R134a (1,1,1,2-Tetrafluoroethane) is a hydrofluorocarbon commonly used as a refrigerant. Its request in cannabis extraction leverages its low toxicity, low boiling point, and favorable solubility properties to gently separate valuable cannabinoids and terpenes from plant material.

- Selective Solvent: R134a selectively extracts cannabinoids with minimal chlorophyll contamination.

- Environmentally Friendly: Compared to butane or propane, R134a presents lower flammability and environmental risks.

- Preserves terpenes: The low-temperature extraction preserves sensitive terpenes, enhancing product flavor and therapeutic effects.

This method fits within cannabis post processing as a precise technique optimized for craft-quality extractions and nutraceutical-grade products.

Why Scale R134a Extraction to Commercial Volumes?

Scaling extraction from craft to commercial volumes addresses market demands for consistent, high-quality cannabis extracts, including:

- Increasing Consumer Demand: The legal cannabis market demands bulk quantities of oils for vape cartridges, edibles, tinctures, and topicals.

- Consistent Quality: Commercial-scale systems integrate automation for reproducible cannabinoid profiles and terpene content.

- Process Efficiency: Larger-scale equipment improves throughput and reduces labor costs.

- Regulatory Compliance: Commercial extraction systems typically adhere better to Good Manufacturing Practices (GMP) and safety standards.

Challenges in Scaling R134a Extraction

Despite its benefits, scaling R134a extraction involves several hurdles, including:

- Equipment Design: Craft extraction units are often batch-oriented and small. Industrial-scale R134a systems must ensure uniform solvent contact and efficient solvent recovery.

- Solvent Handling: Managing larger volumes of R134a requires robust solvent recycling to be economically and environmentally viable.

- Process Control: Temperature, pressure, and flow control systems need to be finely tuned for commercial consistency.

- Extraction Cycle Time: Commercial extractions must minimize cycle times without compromising cannabinoid and terpene profiles.

Best Practices for Scaling R134a Extraction

To successfully scale, cannabis processors should consider the following practices:

1. Modular Equipment Design

Utilize modular extraction equipment enabling capacity expansion without redesigning entire systems. Modular skids allow sequential batch processing or parallel extraction.

2. Automated Process Controls

Implement PLCs (programmable logic controllers) for precise control of temperature, pressure, and flow rates. automation ensures repeatability and reduces operator error.

3. Enhanced Solvent Recovery Systems

Incorporate advanced solvent recovery units to recycle up to 99% of R134a, minimizing costs and emissions.

4. Standardized batch Protocols

Create and document protocols for material preparation, extraction parameters, and post-processing to maintain quality as scale increases.

5. Invest in Skilled Personnel

Train operators and technicians in both cannabis science and industrial refrigeration technologies integral to R134a handling.

Equipment Comparison: Craft vs. Commercial R134a Extraction

| Feature | Craft Extraction | Commercial Extraction |

|---|---|---|

| Batch Size | 1-5 kg flower | 20-200+ kg flower |

| Throughput per Day | 10-50 kg | 500-2,000+ kg |

| Automation | Manual controls | PLC & automated sensors |

| Solvent Recovery | Lower efficiency (80-90%) | High efficiency (95-99%) |

| Capital Cost | Lower initial investment | High initial investment |

Case Study: Transitioning from Craft to Commercial Scale

ABC extracts,a cannabis processor based in California,started with small-batch R134a extraction producing less than 20 kg of concentrate weekly. With rising demand for vape cartridges, they invested in a custom-built 150 kg batch system with enhanced solvent recovery and full automation.

Results included:

- 8x increase in extraction capacity

- Improved cannabinoid consistency & terpene preservation

- 35% reduction in solvent costs due to recycling

- Reduced labor hours from 40 to 15 per week

This case illustrates the scalability potential of R134a extraction technology when paired with thoughtful process engineering.

Practical Tips for Cannabis Processors Scaling R134a Extraction

- Start with Pilot Testing: Before full commercialization, test scale-up parameters to refine extraction cycles and adjust solvent ratios.

- Collaborate with Equipment Manufacturers: Partner with suppliers who understand both refrigeration and cannabis processing.

- Integrate quality Assurance: Embed sampling and testing at every stage to ensure product integrity.

- Plan for Compliance: Keep abreast of state and federal regulations on solvent use and cannabis extraction.

- Sustainability Focus: Prioritize solvent recovery and minimize waste to meet environmental standards.

Conclusion

Scaling R134a extraction from craft operations to commercial volumes represents a pivotal advancement in cannabis processing technology.This method offers a safe, efficient, and terpene-preserving choice that aligns well with quality-focused cannabis production. Leveraging modular designs, automation, and solvent recovery systems enables processors to meet growing market demands while maintaining regulatory compliance and product excellence.

If you’re ready to take your cannabis extraction operation to the next level, understanding the nuances of scaling R134a extraction will equip you with the tools needed for success in this dynamic and competitive industry.

Explore more on cannabis processing equipment and post-processing technologies here on our blog.